Reimagining Cell Therapy Manufacturing, Validated

Trenchant’s AutoCell™ delivers industry-leading performance across all critical unit operations through a fully automated, push-button workflow.

AutoCell™ Optimization of Each Unit Operation Delivers Unprecedented Yield and Speed to Cell Therapy Manufacturing

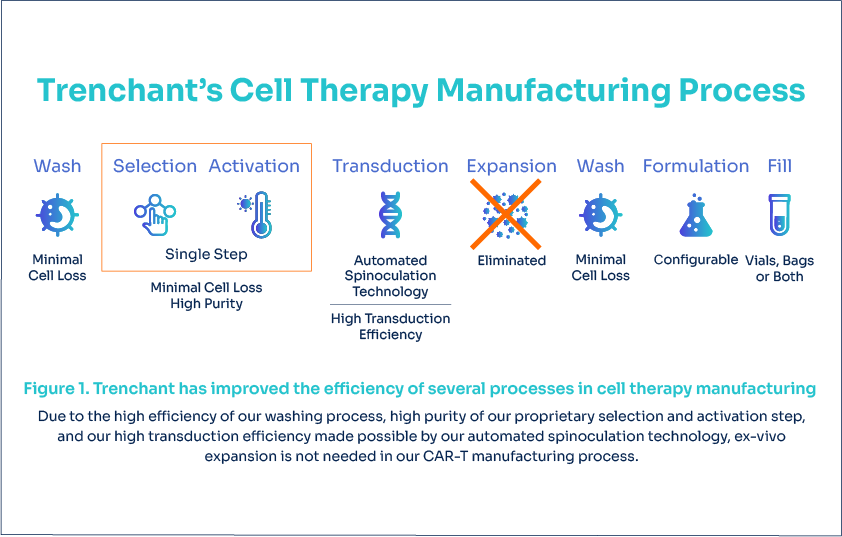

Traditionally, each step in the cell therapy manufacturing process has resulted in significant cell loss, resulting in longer manufacturing times due to needed expansion, and low yield. Trenchant has optimized each unit operation significantly, minimizing cell losses for several key unit operations: apheresis wash, selection, and activation (Figure 1).

Across apheresis wash, selection, and transduction processes, our internal data and third party performance data show that the AutoCell prototype exceeds industry benchmarks within a single, integrated platform.

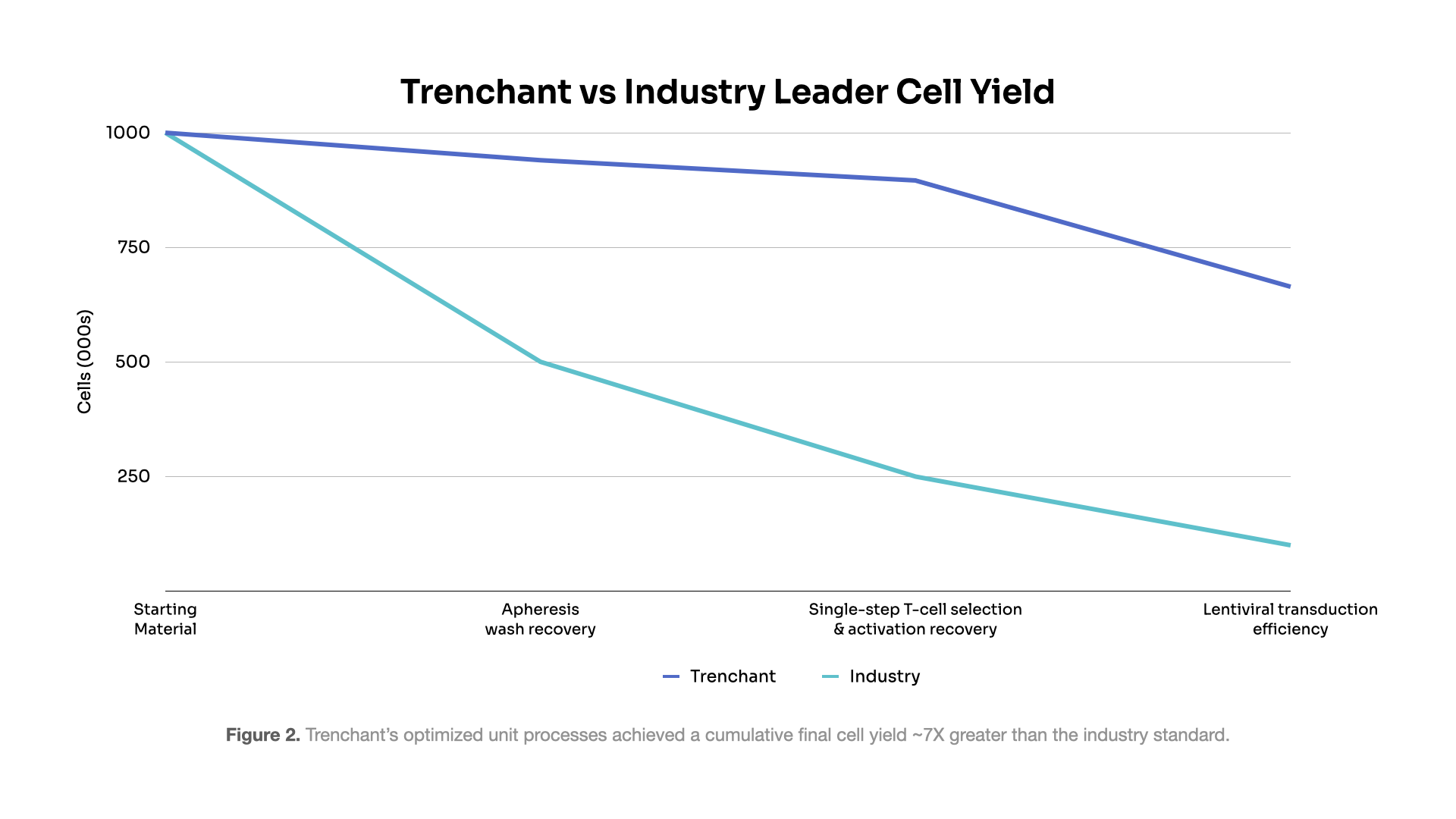

AutoCell Delivers Up to 7X Improvement in Therapeutic Cell Yield

Internal and third-party performance data demonstrate a ~7-fold improvement in gene-modified cell yield compared to current market-leading systems by maximizing cell recovery across several unit operations (Figures 2 and 3).

Industry standards referenced from ‘Development of an automated manufacturing process for large-scale production of autologous T cell Therapies.’ Accessed Jan 29, 2026.

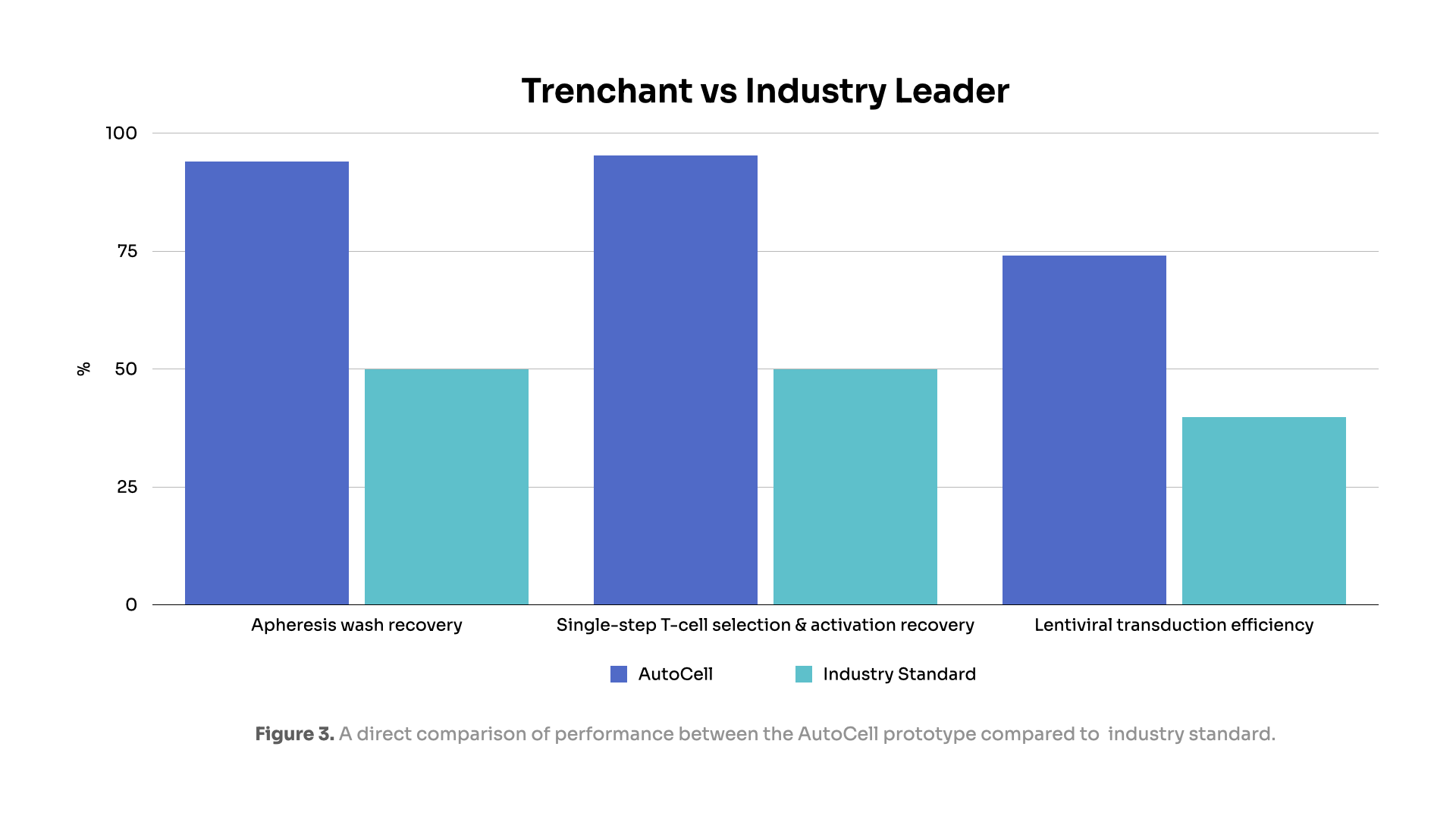

AutoCell’s Process Improvements

Apheresis

Washing Recovery

94.3%

Compared to 50.0% industry standard

Single-Step T-Cell

Selection Recovery

96.4%

Compared to 49.9% industry standard

Single-Step T-Cell

Selection Purity

98.4%

Compared to 86.2% industry standard

Lentiviral Transduction

Efficiency

74.1%

Compared to 39.9% industry standard